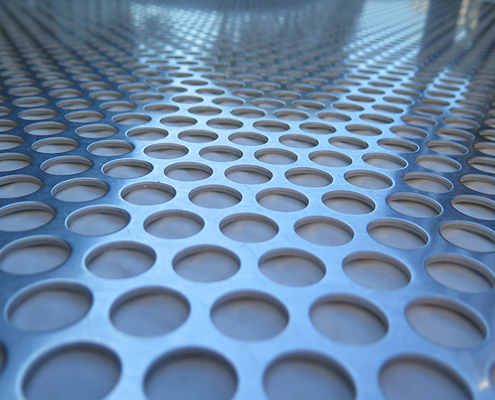

CNC Turret Punching

A CNC (Computer Numerical Control) punch press is a type of machine tool used in the manufacturing industry to cut, shape, and form sheet metal and other materials. It's an automated system that uses computer programming to control the movement of a punch and die set to create holes, shapes, and patterns in the material.

Key features and components of a CNC punch press include:

Control System

The heart of the CNC punch press is its control system, which consists of a computer and software that interpret the part design and generate the necessary commands to control the machine's movements.

Punch and Die Set

The punch is a tool that moves vertically and applies force to the material, while the die is a stationary tool that provides the counterforce. By using different punch and die combinations, various hole shapes and sizes can be created in the material.

Turret

Modern CNC punch presses often have a rotating turret that holds multiple punch and die sets. This allows for quick tool changes, reducing downtime and increasing productivity.

Material Clamps

To hold the material securely in place during the punching process, clamps are used. These clamps can be repositioned as needed to accommodate different part sizes and shapes.

CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are used to design parts and generate CNC programs that guide the punch press. These programs specify the tool path, feed rates, and other parameters for cutting and forming operations.

Tooling

At ALMEC we have an extensive range of tooling including cluster tools that allows us to quickly process your job without the delay of waiting for custom tooling. All our tooling is maintained to the highest standard to ensure tool sharpness and quality of the end product.

Our 1225 LVD punch press can process sheets 1200mm x 3000mm with 1 repositioning and thickness up to 1.5mm stainles steel, 3mm steel and 5mm aluminuim.

CNC punch presses offer high precision, repeatability, and the ability to create complex patterns and shapes efficiently.

The automation provided by CNC technology reduces the need for manual labor, leading to increased productivity and improved consistency in the manufacturing process.